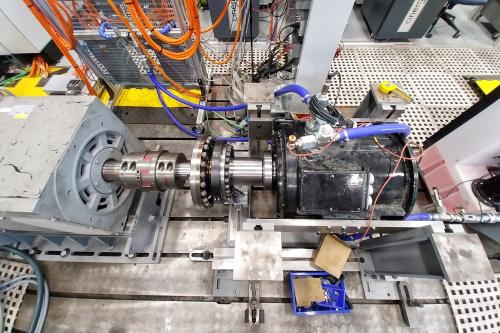

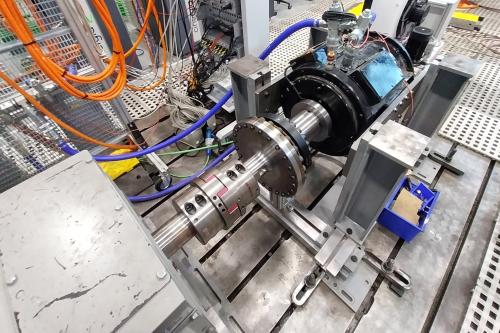

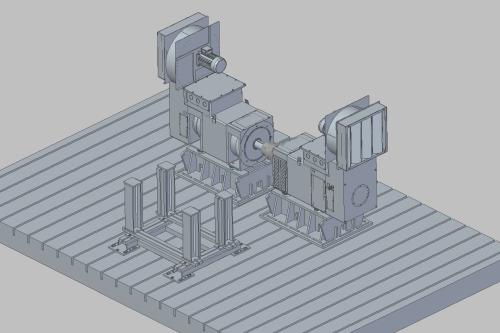

At Sintemar, we specialize in the design and manufacturing of frames and rollers for a wide range of industrial applications. Our approach spans from mechanical fastening calculations to creating customized solutions that integrate technical specifications for engines up to 200 kW, with operating ranges between 1500 and 15,000 rpm.

Our services include:

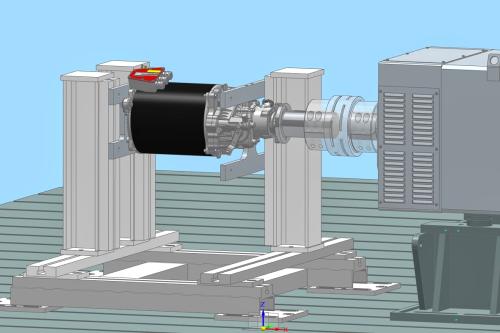

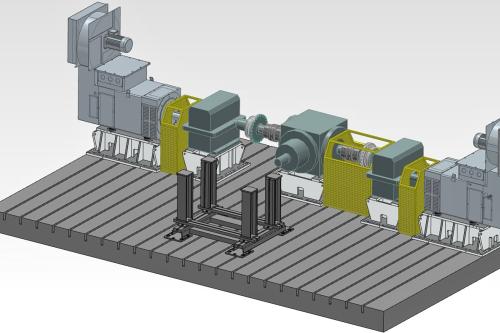

- Customized design of frames and rollers: We tailor each project to the specific needs of our clients, ensuring the integration of machinery trains, engines, and other components.

- Optimized mechanical interfaces: We develop efficient mechanical interfaces to ensure precise adaptation of the frame to the unique characteristics of each system.

- Integration of MECLEV mechanical chocks: We consider the installation of MECLEV chocks in the design to ensure stability and performance in operations.

- Selection and balancing of couplings: We select the most suitable couplings based on torque, rpm, and power, managing the balancing according to the specific characteristics of each frame.

- 3D simulation and design: We use advanced virtual mockup technologies and 3D layouts to visualize and optimize the design before implementation.

- Detailed technical drawings: We employ tools like Solid Edge for creating 3D models and renders, as well as AutoCAD for developing 2D technical drawings.

- 2D and 3D design.

- Turnkey project solutions.

Our designs are aimed at maximizing operational efficiency and meeting the dynamic demands of test benches and other industrial environments, ensuring robust and durable solutions for every client.

Service provided in:

- España

- Portugal